by: Luke Deamer, Erica Russell and Jacquetta Lee, Centre for Environment and Sustainability, University of Surrey

Introduction

We all know the issues of multiple industry PQQs; often irrelevant, time consuming, repetitive and with requests for similar, but slightly different, standards and accreditations. With such barriers, is sustainability being addressed in PQQs? If so, do they make any difference to the final built asset? Our research, reviewing multiple PQQs as they flow across the supply network, looks to answer these questions.

Despite different PQQ formats, their purpose is clear; they provide information to support qualification as an approved supplier (CIPS, 2019), or put another way, ‘to assess the overall competency of a company’ (SCSS, 2018). Importantly, research into the effectiveness of PQQs indicates that ‘technical expertise, past success, time in business, work methods and working capital’ significantly impact on contractors’ performance across time, cost and quality success’ (Doloi, 2009) in essence, there is a correlation between PQQ criteria and project success (Acheamfour, Kissi and Adjei-Kumi, 2019).

This article considers PQQ sustainability data captured down the supply chain, from clients down to raw material suppliers. We consider the types of sustainability information requested at each stage of the supply chain and ask whether they help meet the objective of building sustainable assets. To meet this goal, we propose a PQQ must answer three key questions:

- Does a company’s work methods support sustainability, both within their own organisation and on-site?

- Does their technical expertise include the ability to offer sustainable products and services?

- Do they manage their own supply chains to screen for sustainability?

Passing on the message

Client to main contractor

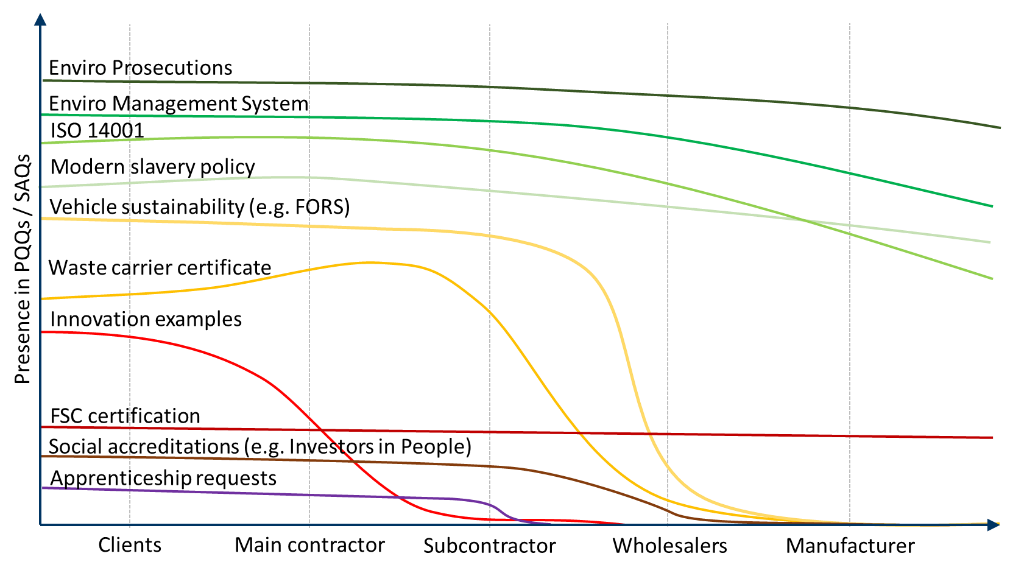

Firstly, it is worth noting that we frequently found ‘sustainability’ to be disconnected from questions on technical expertise or work methods. Rather than being a cross cutting theme, it was identified as a separate topic. Client PQQs varied hugely; for large framework contracts or high value work, many PQQs included open-ended questions, seeking to gain insight beyond certification and policies. They asked main contractors ‘how’ they would enhance sustainability and frequently required project-based examples. Large infrastructure projects or framework agreements required highly detailed responses whilst others, typically private builds, were minimal. Clients, once almost exclusively focused on establishing environmental competency through environmental policies, environmental management systems, including ISO14001, waste management strategies and prosecution data, are now requiring social metrics (fig 1). Main contractors are being asked about their support for stakeholder engagement, community regeneration and the experience they have in delivering ‘social value’. Publicly funded contracts ask for information on their approach to apprentices, the local workforce and the contracting of SME suppliers. Only a small number asked at PQQ stage for information on the main contractor’s approach to sustainable supply chain management, modern slavery issues and risk. Surprisingly, few clients included carbon reduction approaches including the use of renewable energy in the PQQ and those that did were primarily publicly funded. Weighting of sustainability questions was generally less than 5% of the total PQQ.

Main contractor to subcontractors

Main contractors were selective in passing client sustainability questions to subcontractors, the most common being on environmental prosecutions and the now well established, ISO 14001 certification or other environmental management systems (EMS) (fig. 1). Both of these now appear to have been incorporated in main contractor PQQs, regardless of client demand. Only a small number of PQQs required information on carbon or climate change approaches. Bribery, equal-opportunities and modern slavery policies were also incorporated into a large proportion of PQQs; ensuring legal compliance.

Unlike many client PQQs, main contractors required information in a transactional format, typically through requests for standard certifications, legal positions and statistics. Quantitatively assessed answers were quicker to assess than narrative responses and required minimal staff expertise on sustainability. Questions asking for examples of previous work on sustainability and innovation, were rarely passed on to subcontractors, thus potentially missing sustainability innovations, even if they were later proposed in the tender. For the smaller value projects there was evidence that some sustainability questions were ‘lost’. Some of these lost questions reflect the short time span, lower value and specialist tasks subcontractors carry out on site. Indeed, this may make some questions irrelevant for particular work.

Subcontractor to wholesalers and manufacturers

Subcontractors set PQQs for their material suppliers and further specialist sub-subcontractors. Once again, like main contractors, the number of sustainability questions were very dependent on the client and project; in large infrastructure projects, subcontractors typically passed on the main contractors PQQ. Therefore, alongside ISO 14001 and environmental prosecutions, these public project PQQs could include information on waste management and the use of ‘sustainable’ materials. Only a few PQQs included carbon reduction and the use of renewable energy.

It was common in the lowest value projects for subcontractors to have no sustainability criteria in their PQQs at all (fig. 1). We believe this is because subcontractors consider sustainability sufficiently covered in supplier approval questionnaires (SAQs). Yet whilst these SAQs almost always gathered environmental prosecution data and ensured an EMS was in place, they did not pass on any project-specific criteria; likewise, SAQs were frequently approved with sustainability questions left blank. We identified that a small number of subcontractors varied their PQQs questions based upon their risk of exposure by the supplier, the size of their contract or the number of contracts with a supplier. Whilst this may have helped prioritise the capacity of smaller companies to respond, there was no clear relationship to the sustainability demands of the built asset.

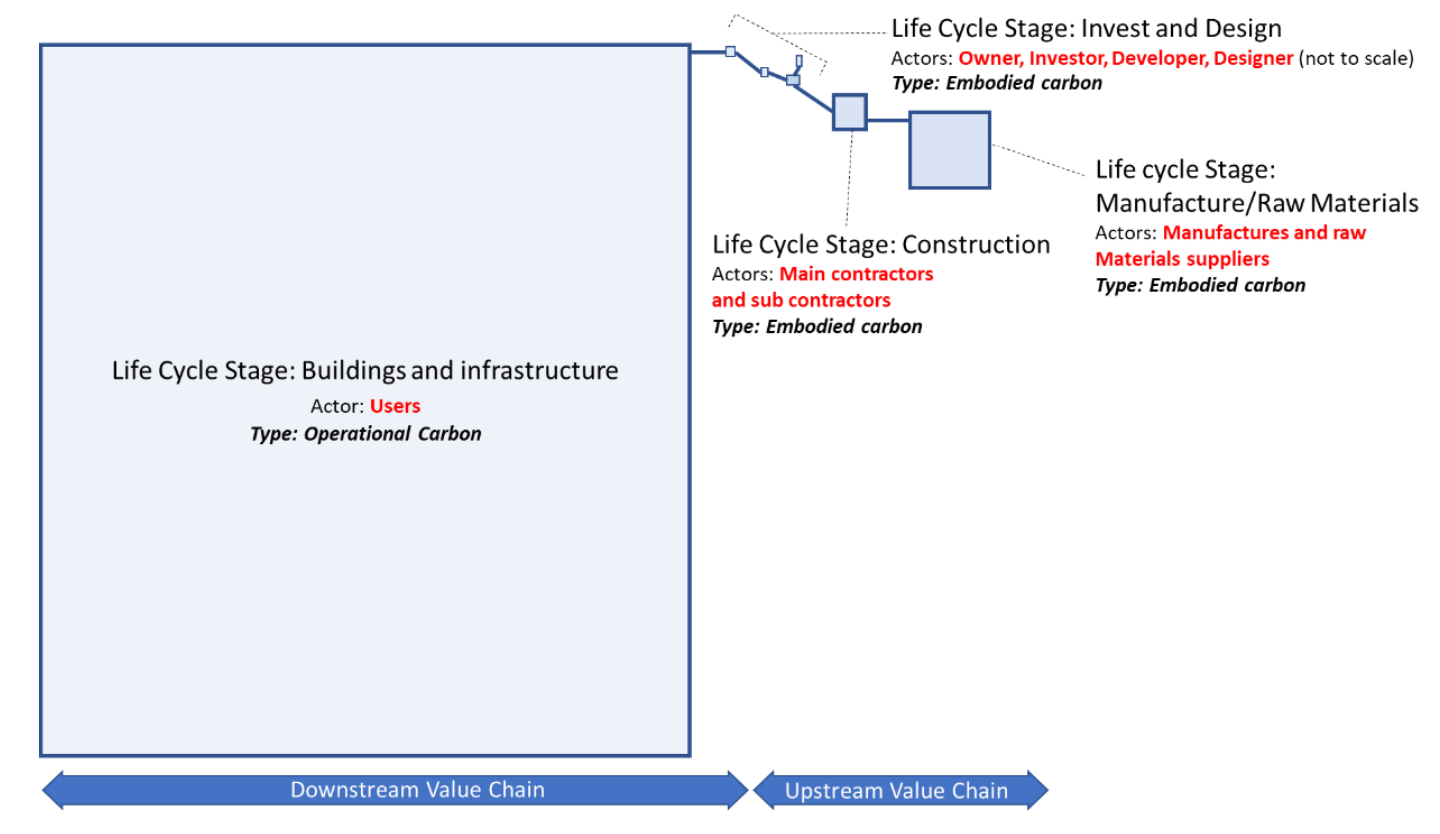

Except for large infrastructure projects, signature builds or ‘sustainable build’, no sustainability criteria were passed down to wholesalers or manufacturers; only SAQs and a contract remained. Invoice-only bids were more common than PQQs and any remaining PQQ questions almost exclusively focused on insurance, quality, price, capacity and service. Although not directly reviewed, industry sources confirmed that SAQ sustainability questions were optional, limited and answers frequently incomplete. Some of these barriers are structural, as many wholesalers requiring a large stock to service multiple contractors across many thousands of projects. Therefore, whilst they may offer more sustainable materials for specific jobs, they are unlikely to implement sustainability criteria for the whole business based on individual contracts. Bulk purchasing also means that wholesalers are less likely to pass on additional sustainability criteria from specific jobs down to manufacturers. Yet, many manufacturers, responsible for high embodied environmental impacts (fig 2) are highly regulated and have initiated many efficiency programmes. Limited ranges and longevity of production on permanent sites, has enabled many companies to benefit from sustainability initiatives. Many manufacturers, who have developed products with improved sustainability attributes, are frustrated that PQQs and tenders fail to address these questions and that demand remains low.

(Diagram, to scale, from data provided by Green Construction Board ‘Routemap’, (Ove Arup and Partners Ltd, Centre and WRAP, 2013). Source: (Russell, 2019).

The PQQ feedback cycle

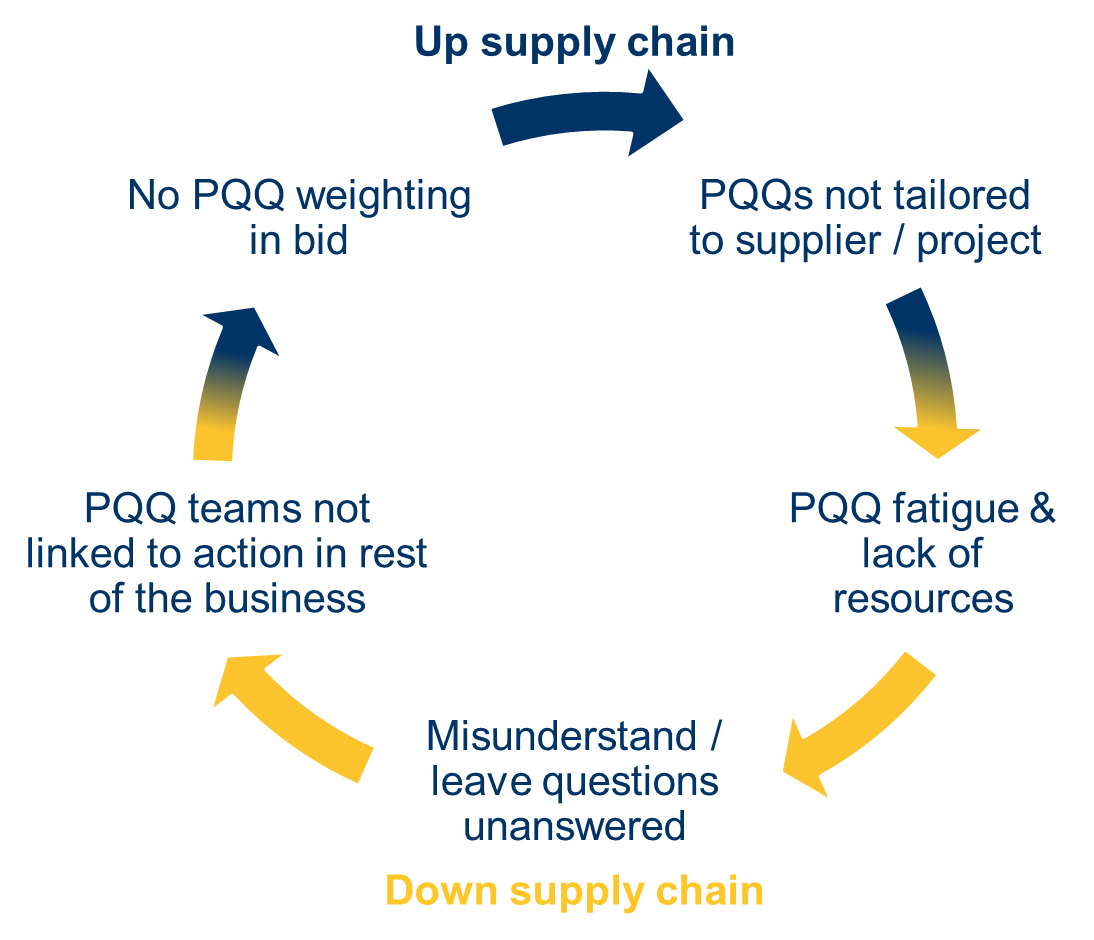

Beyond the basic sustainability requirements, most PQQ sustainability questions appear to be stuck in a feedback cycle (fig 3). Despite rising client demand, particularly among large public-funded infrastructure projects, integrated sustainability questions are yet to gain traction in PQQs. A sector-wide lack of sustainability PQQ importance appears to be reflected in low knowledge level amongst staff responding to PQQs and thus poorer quality answers. It can be argued that this devalues sustainability questions and reduces upstream supply chain weighting and feedback. Likewise, inapplicable and irrelevant questions that are passed down the supply chain risk completely devaluing PQQs.

The number of PQQs, which could number over 1000 per year for a large subcontractor, also introduces an element of fatigue which can further decrease the quality of responses and reduces the likelihood of these priorities being passed down the supply chain. As the value of each project becomes less down the supply chain, there is likely to also be a corresponding decrease in the size and expertise of teams dealing with PQQs.

Our research also discovered a disconnect between the aim of the client when including sustainability questions in their PQQs and subcontractors’ perception. This is best illustrated in example questions; whilst clients used these as a tool to demonstrate experience and innovation, subcontractors often viewed them as a time-consuming, subjective and of little impact on the bid. Likewise, since subcontractors and suppliers have specialist roles, parts of generic PQQs can easily become irrelevant, devaluing the whole PQQ for subcontractors.

We also found that in some cases the PQQ regime operated by main contractors was little more than a “box-ticking exercise”. In 8% of cases we found that PQQs were being completed by Subcontractors after the award of a contract, often as a condition of payment, rather than anything to do with a selection process prior to award. We also found that in many cases main contractors were repeatedly asking the same subcontractor to complete exactly the same PQQ, many times during the year. In the worst example, one of the UK’s largest contractors required the subcontractor to complete the same form ten times in a 12 month period (Deamer, 2019).

Conclusions

Unlike the majority of PQQ questions, which focus both on organisation and on-site performance, sustainability questions frequently failed to identify sustainable site performance. An EMS does demonstrate the ability of companies to implement sustainable procedures but does not directly address on-site sustainability performance and sustainable methods can remain unrealised for an asset.

PQQs therefore appear to contribute very little towards holistic sustainability. We live in a country that has declared a climate emergency, so where are the carbon criteria? Low emission zones are springing up across cities, yet we see no early selection for companies able to manage particulate and engine efficiency criteria. All PQQs fall far short of capturing and rewarding any wider sustainable expertise. There are construction companies in the supply chain who are innovating and improving sustainability, but most PQQs fail to identify and capture their work. The industry struggles to implement sustainable supply chain management, with sustainability questions, criteria and priorities weakened as they pass down the supply chain. The result is a supply chain that is opaque to the sustainability demands of clients, where indeed these exist.

There are some success stories; modern slavery legislation, FSC demands and environmental prosecutions are all relatively consistent up or down the chain. Yet only individual companies are going beyond these criteria, rather than this forming a concerted effort by clients, standard PQQs or trade bodies. Every stage of the supply chain must shoulder some responsibility. Sustainable supply chain management requires companies to translate priorities and ask the right questions, as well as to accurately answer them. Therefore, the current PQQ feedback cycle of irrelevant questions and poor responses needs to be broken if sustainability is to percolate down the supply chain.

Understanding where sustainability is lost in translation through the supply chain is essential for understanding the whole life cycle sustainability of a built asset. In the future, PQQs may be the tool for companies to capture their whole supply chains’ sustainability performance, expertise and innovation. Until then, each stage in the supply chain can begin using PQQs to look beyond the questions themselves, towards their impact on the sustainability of the final built asset. Only if the whole supply chain properly values PQQs, can PQQs be a valuable tool for managing supply chain sustainability.

References

Acheamfour, V. K., Kissi, E. and Adjei-Kumi, T. (2019) ‘Ascertaining the impact of contractors pre-qualification criteria on project success criteria’, Engineering, Construction and Architectural Management, 26(4), pp. 618–632.

CIPS (2019) Glossary of Procurement Terms: PQQ. Available at: https://www.cips.org/en/knowledge/glossary-of-terms/#P (Accessed: 14 November 2019).

Deamer, L. R. (2019) Proper use of pre-qualification questionnaires can inject value into projects., Construction News. Available at: www.constructionnews.co.uk/agenda/opinion/proper-use-pre-qualification-questionnaires-can-inject-value-projects-03-09-2019/ (Accessed: 20 November 2019).

Doloi, H. (2009) ‘Analysis of pre‐qualification criteria in contractor selection and their impacts on project success’, Construction Management and Economics, 27(12), pp. 1245–1263.

Ove Arup and Partners Ltd, Centre, T. C. and WRAP (2013) Low Carbon Routemap for the UK Built Environment. London: Green Construction Board.

Russell, E. (2019) Leading Role or Bit Player? Main contractors, supply chain and sustainable construction. University of Surrey.

SCSS (2018) Sustainable Procurement, Supply Chain Sustainability School. Available at: https://www.supplychainschool.co.uk/ (Accessed: 12 July 2019).

Contact Details: Luke Deamer l.deamer@surrey.ac.uk ; Erica Russell e.f.russell@surrey.ac.uk ; Jacquetta Lee j.lee@surrey.ac.uk